Boilers play a crucial role in providing essential heat and power to buildings. Gaskets are a small component of a boiler system that supports efficiency by ensuring a tight seal. However, like any part, gaskets require proper maintenance to ensure longevity and peak performance. In this blog, we’ll discuss the importance of maintaining gaskets in boilers, common misconceptions and offer practical tips for an effective maintenance routine.

Understanding the Anatomy of Gaskets

Gaskets act as seals, preventing leaks and ensuring the efficient operation of boilers. They come in various materials, each tailored to specific operating conditions. Common materials include rubber, graphite, and metal.

Boiler Chemistry vs. Gasket Failure Myth

One prevalent misconception is blaming boiler chemistry for gasket failure. Contrary to popular belief, it’s not the chemicals causing the breakdown. Gaskets deteriorate over time due to the combination of factors, such as pressure, heat, and improper installation practices. Recognizing this fact is key to implementing effective maintenance strategies.

Signs of Gasket Wear and Tear

To maintain gaskets effectively, it’s crucial to identify signs of wear and tear. Early indicators include weeping or leakage. Monitoring these symptoms allows for proactive intervention, preventing more severe issues down the line. Regular inspections during routine maintenance checks can make a significant difference.

Best Practices for Gasket Maintenance

- Regular Inspections: Incorporate gasket inspections into routine boiler maintenance. Check for signs of wear, leaks, or visible damage.

- Proper Installation Practices: Ensure gaskets are installed correctly, avoid overtightening or improper fitting. Following manufacturer guidelines is paramount.

- Schedule Replacements: Instead of reusing gaskets, schedule regular replacements during boiler openings. This proactive approach minimizes the risk of unexpected failures.

- Understanding Deposits: Recognize that observable deposits are symptoms, not causes, of gasket deterioration. This understanding prevents misdiagnosing the root issues.

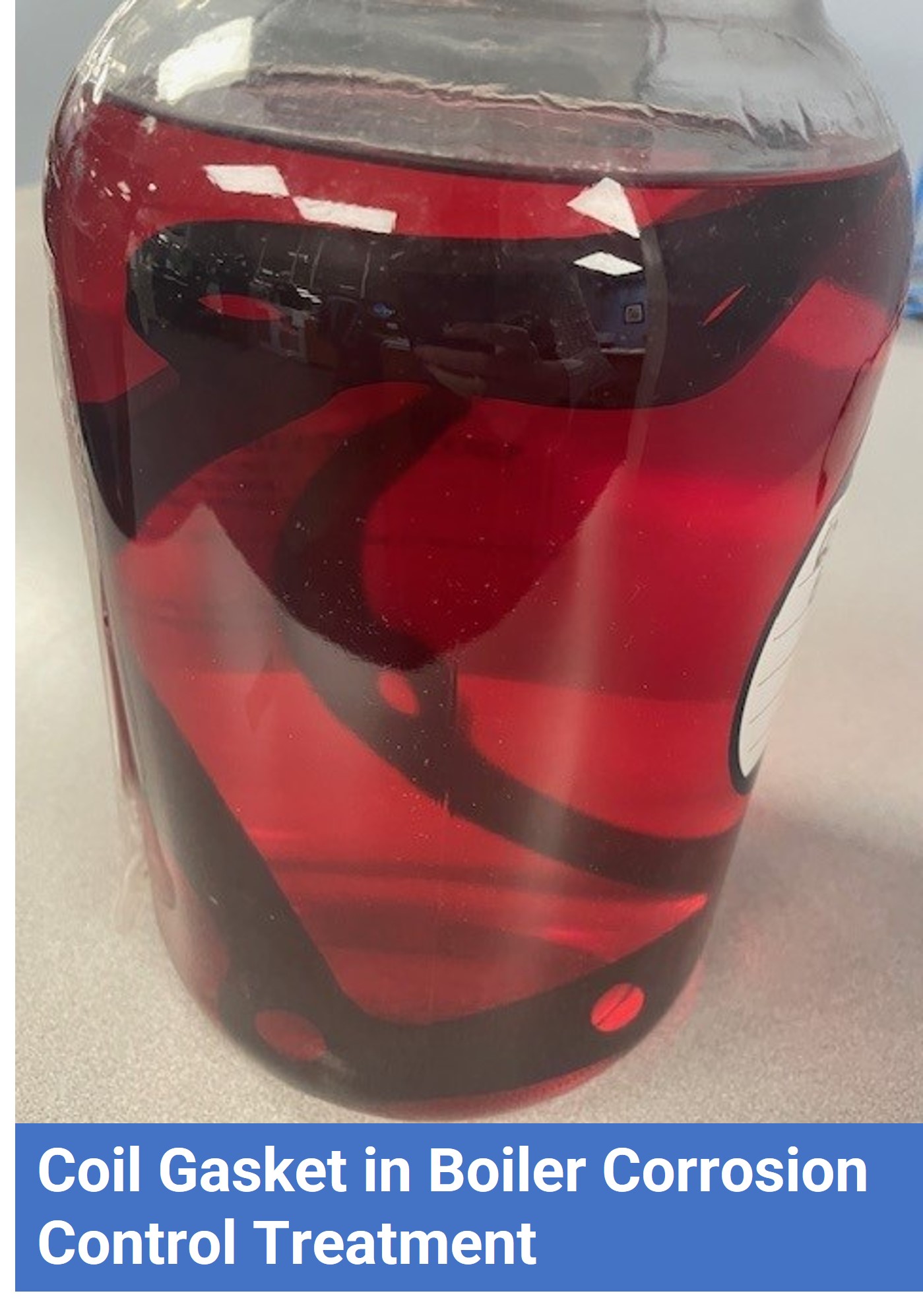

Longevity of Gasket in Concentrated Solutions

Illustrating the effectiveness of proper maintenance, we showcase a common gasket submerged in a concentrated boiler corrosion control treatment for nearly a decade. Despite the harsh conditions, the gasket remains in perfect condition, emphasizing the impact of quality maintenance practices.

Proactive Gasket Maintenance in your Boiler System

The longevity and efficiency of boiler systems heavily depend on the often-overlooked gasket. By debunking myths, understanding warning signs, and implementing best practices, we can ensure that these small, yet vital components continue to play their crucial role. Proactive gasket maintenance not only extends the lifespan of boilers but also contributes to enhanced safety and operational efficiency.

Partner with Boiler System Experts

Choose Metro Group’s boiler system experts for unparalleled performance and efficiency. Our seasoned professionals handle everything from installation to proactive maintenance, ensuring minimal downtime and mitigating risks. By partnering with us, you tap into customized solutions crafted to meet your building’s unique needs, guaranteeing the reliable and seamless operation of your boiler systems.

Looking for honest and excellent boiler water treatment? Metro Group has been the trusted source for building solutions since 1925. Contact us for a free quote on all your water treatment needs.