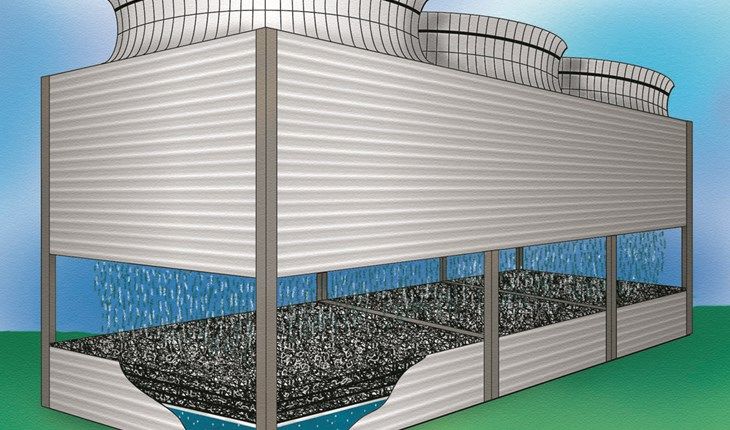

From the water treatment industry’s perspective, the practice of controlling the proliferation of microbial fouling in HVAC/Industrial cooling water systems has traditionally been focused on keeping algae, slime and fungus in check. Without proper control, organisms will colonize, grow, and turn into biomass and biofilm. Displaced biomass can lead to restrictions in flow, loss of heat transfer and other serious water-borne problems. In addition, a longer-term challenge is that accumulated bacterial slimes (biofilm) will lead to microbiologically influenced corrosion, metal loss and system failure. Also, due to recent regulatory developments, the industry now has another objective to contend with. This is to reduce the potential formation of disease-bearing organisms such as Legionella Pneumophila. So, effective microbial control is at the center of overall cooling system performance as well the health of building occupants.

Cooling tower owners have numerous tools at their disposal. These tools include application of chemical biocides, cooling tower chemical disinfections, and the selective use of mechanical support methods. Among the mechanical support methods owners can rely upon we find deck covers (to shield sunlight), recirculating water filters (sand or media) to remove suspended solids continuously, basin cleaning filters to keep pans deposit free, and even air-intake screens to prevent additional dirt loading. Cooling water biocides are applied routinely and typically involve the use of two different product categories – oxidizing and non-oxidizing micro-biocides. These materials are designed to destroy existing organisms and also prevent new ones from growing. The strategy of using two separate chemical micro-biocides is to ensure that cellular destruction is complete, and that strains do not develop immunity to resist treatments.

Owners working with industry professionals have numerous monitoring tools at their disposal. Cooling tower inspections should be coupled with the use of microbiological testing. Micro testing is part of effective Water Management Plan development and includes testing for halogen reserves, bacteria and cellular activity, as well as specific testing for Legionella. Best practice might also incorporate the use of bio-film detection strategies. In conclusion, microbiological control of Industrial and HVAC cooling waters requires careful planning and resource allocation. An appropriate selection of the tools now available to building owners can be selected and implemented to prevent problems, preserve capital equipment, and ensure the health of building occupants.

By:

John D. Caloritis, CWT

Technology Director

The Metro Group, Inc