Softener Application

The potential for scale and deposit buildup exists in every raw water supply. The ability of the sodium zeolite softener to reduce this potential effectively and economically makes this an ideal pretreatment for boiler feedwater and many types of chemical process waters. Compared to other softening methods, sodium zeolite units offer many advantages:

- The treated water has a very low scaling tendency because this method reduces the hardness level of most water supplies to less than one part per million (ppm).

- Operation is simple and reliable; automatic regeneration controls are available at a reasonable cost.

- Regeneration is accomplished with inexpensive, easy-to-handle salt (NaCl).

- Waste disposal usually presents no problem.

- Within limits, variations in the water flow rate have little effect on the treated water quality.

- Efficient operation can be obtained in almost any size unit, making sodium zeolite softeners suitable for both large and small installations.

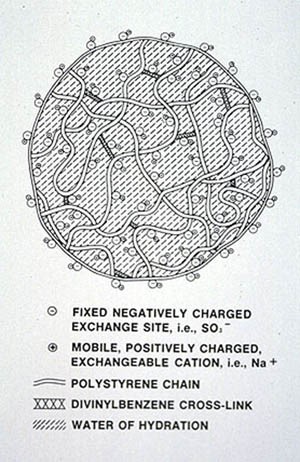

The Ion Exchange Process

Ion exchange is the process in which materials exchange one ion for another, hold it temporarily, and release it to a regenerating solution. These materials are widely used to treat raw water supplies which contain dissolved salts. Today the most commonly used material is an ion exchange resin. Resins are plastic beads to which a specific ion has been attached – an ion which is exchanged for other ions in the water supply (Figure 1). Once the resin has given up or exchanged most of its exchangeable ions, it is said to be exhausted and needs to be regenerated by coming in contact with a strong solution of ions called the regenerate. The regeneration procedure will be explained in detail later in this article.