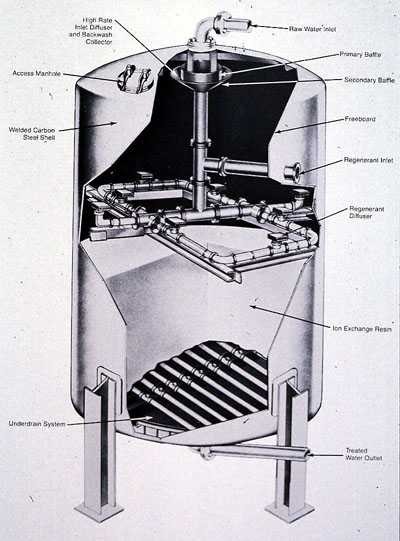

Sodium zeolite softener systems consist of a softener tank, valving and a means of transporting brine (salt solution) to the softener tank. The tank includes a service and rinse water inlet distributor, freeboard or the headspace from the top of the resin bed to the top of the vertical wall of the tank, a regenerant distributor, a bed of ion exchange resin and sometimes a supporting medium or outlet distribution system.

The inlet assembly is designed to evenly distribute the incoming water. It also acts as a collector for the backwash water that goes to the sewer.

The feedboard space allows the resin to expand without loss to drain during the backwashing. It should be designed to permit a minimum of 50% expansion.

The regenerant distributor located above the resin bed, spreads the brine uniformly over the resin beads.

A bed of resin, operating in the sodium cycle, softens the water. The quantity of resin used depends on the raw water hardness, the quantity of water to be treated per regeneration, flowrate, and the regenerant level employed.

An underdrain system evenly collects the treated water, waste brine and rinse water, and distributes the backwash water.

It is not unusual to have a valving system that consists of either a valve nest or a single, multiport control valve. A nest of six (6) main valves is needed for the service inlet and outlet, backwash inlet and outlet, brine inlet and rinse outlet. The valves may be either manually operated or any variety of air-, water- or motor-operated automatic valves. A single, multiport control valve may be used in place of the valve nest. As the multiport valve moves through a series of four positions, the ports in the valve direct the flow of water in the same manner as the opening and closing of separate valves.

The brining system consists of a salt dissolving/brine – measuring tank. It is used to prepare a saturated brine solution. This tank frequently has a float – operated valve to control the fill and drawdown level and thus, the quantity of brine added to the softener. Usually an eductor transfers the saturated brine to the softener and dilutes the saturated brine with inlet water to the desired concentration for resin regeneration.

A future article will include a guide to softener troubleshooting along with additional information on softener operation and maintenance.